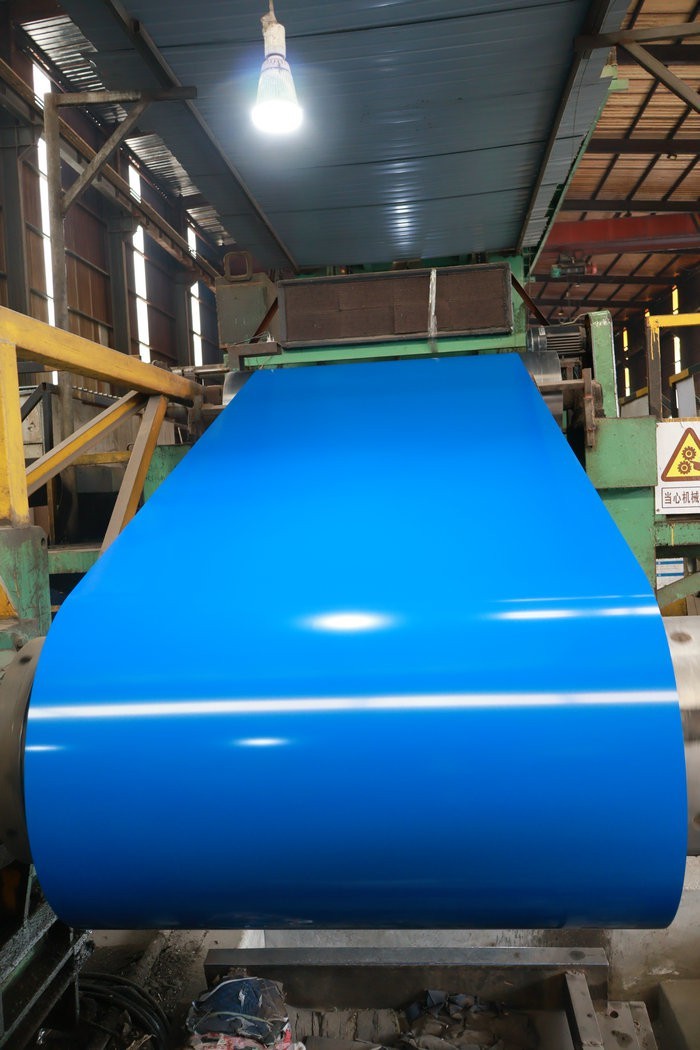

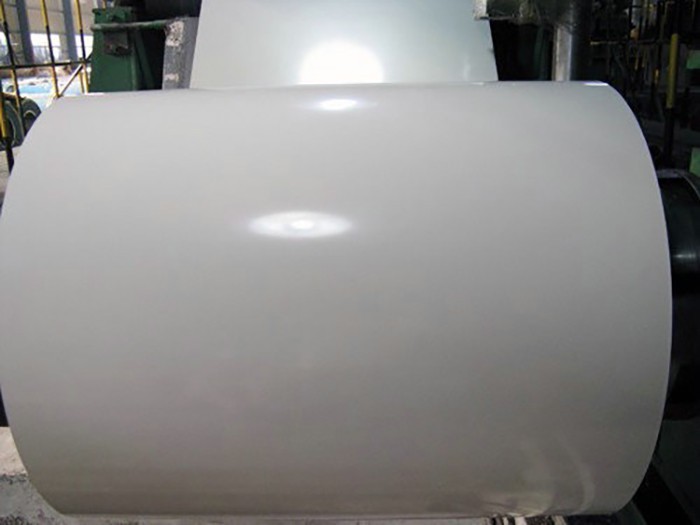

In the fields of modern industry and construction, the selection of materials plays a crucial role in the quality, appearance, and performance of products. Color coated sheets, as a new type of material, are gradually emerging in various industries and receiving increasing attention. So, what exactly is a

color coated sheet and what are its unique features? Below, we will unveil its mysterious veil for everyone.

Color coated sheet is a composite material made by coating one or more layers of organic coatings on the surface of a metal substrate and subjecting it to high-temperature curing treatment. It combines the strength and processability of metal substrates with the decorative and corrosion-resistant properties of organic coatings, and is widely used in fields such as construction, home appliances, and transportation. The following are its core points:

1. Structural composition

1. Substrate: usually cold-rolled steel plate, galvanized steel plate (such as hot-dip galvanized, electroplated galvanized) or aluminum plate, providing mechanical strength and support.

2. Coating:

Primer: Enhance the adhesion between the coating and substrate of color coated sheets, commonly using epoxy resin, polyester resin, etc.

Topcoat: Provides decorative and protective properties, common types include:

Polyester: Low cost, average weather resistance, suitable for indoor or short-term outdoor use.

Silicon modified polyester: better weather resistance than PE, suitable for moderate environments.

High weather resistant polyester: better corrosion resistance and color retention, suitable for long-term outdoor use.

Polyvinylidene fluoride: With excellent weather resistance and a lifespan of over 20 years, it is used in high-end construction.

Plastic sol: has a soft surface, is scratch resistant, and is commonly used in household appliances.

2. Manufacturing process

1. Continuous coating method: The metal coil is passed through an automated production line and sequentially subjected to cleaning, pretreatment, primer coating, topcoat coating, baking and curing steps to form a uniform coating.

2. Key parameters: coating thickness (usually 15-30 μ m), curing temperature (200-250 ℃), coating adhesion, etc.

3. Core Features

1. Corrosion resistance: The coating isolates the metal from contact with the external environment, extending its service life.

2. Decorative: Color coated sheets can be customized in terms of color, glossiness (matte, high gloss), and texture (metallic texture, wood grain, etc.).

3. Processability: capable of stamping, bending, and welding, suitable for complex shape requirements.

4. Environmental friendliness: Some coatings (such as PVDF) are non-toxic and recyclable, meeting green building standards.

4. Application Fields

1. Construction industry:

Roofs and walls (such as industrial plants, warehouses, sports halls). Doors, windows, partitions, and decorative components.

2. Home appliance industry:

Refrigerator, washing machine, air conditioner casing. Internal lining plates for microwave ovens, ovens, etc.

3. Transportation sector:

Automotive interior panels, subway car interior walls. Container and truck carriages.

4. Other:

Solar brackets, agricultural greenhouses, furniture, etc.

5. Advantages and limitations

1. Advantages:

Compared to traditional spray painting, the coating is uniform, efficient, and cost-effective. Durable colors reduce maintenance costs.

2. Limitations:

The coating thickness of color coated sheets is limited and may peel off in extreme environments. When cutting or welding, the edges need to be treated to prevent rusting.

6. Development Trends

1. High performance coating: Develop coating materials that are more weather resistant, self-cleaning, and antibacterial.

2. Environmental Protection: Promote water-based coatings and low VOC (volatile organic compound) formulations.

3. Intelligence: Integrated sensors or functional coatings (such as insulation and conductivity).

Color coated sheets have demonstrated strong competitiveness in numerous fields due to their unique advantages. It not only meets the diverse demands of the market for material performance and appearance, but also performs well in environmental protection, energy conservation, and cost control. With the continuous advancement of technology, color coated sheets will continue to innovate in the future, providing better and more efficient support for the development of various industries and becoming an important force driving industry progress.

Language

▼

Language

▼