Language

▼

Language

▼

More Language

In the field of modern architectural decoration materials, as demands for building aesthetics, environmental performance, and durability continue to rise, various metal decorative plates undergo constant innovation and iteration. Among these, color-coated aluminum plates have gained widespread popularity due to their lightweight nature, corrosion resistance, diverse appearance options, and excellent workability. They are extensively used in roofing and wall systems, decorative curtain walls, home interiors, transportation, and other sectors, establishing themselves as a highly favored product within the metal plate category.

Color-coated aluminum plates are metal plates manufactured using high-purity aluminum or aluminum alloy plates as the substrate. Through processes such as roll coating and baking, one or multiple layers of organic coatings are applied to the aluminum surface. This results in a rich array of colors and textures while imparting multiple properties including corrosion resistance, oxidation resistance, and decorative appeal.

It retains aluminum's inherent characteristics of light weight, excellent formability, and strong weather resistance, while enhancing its aesthetics and durability through the coating. Consequently, it enjoys high market recognition in architectural decoration systems. Simply put, Color-Coated Aluminum plate = Aluminum Base Material + Pre-treatment Layer + Coating System + Baking Curing Protection.

Color-coated aluminum plates primarily consist of the following components:

Commonly selected from 1000, 3000, and 5000 series aluminum alloys:

- 3003 and 3004 series are used for roofing systems, offering good formability.

- 5052 and 5005 series are used for curtain walls, providing higher strength and better corrosion resistance.

Enhances adhesion between the coating and aluminum substrate while improving corrosion resistance.

Coatings are selected based on environmental conditions and performance requirements:

- Polyester (PE): Lower cost with vibrant colors

- Silicone-modified Polyester (SMP): Superior weather resistance

- Fluorocarbon coating (PVDF): Exceptional UV resistance and aging resistance, with outdoor service life up to 20–30 years

Provides surface protection during transportation and processing to prevent scratches.

The synergistic interaction of these layers endows colored coated aluminum plates with both aesthetic appeal and long-term durability.

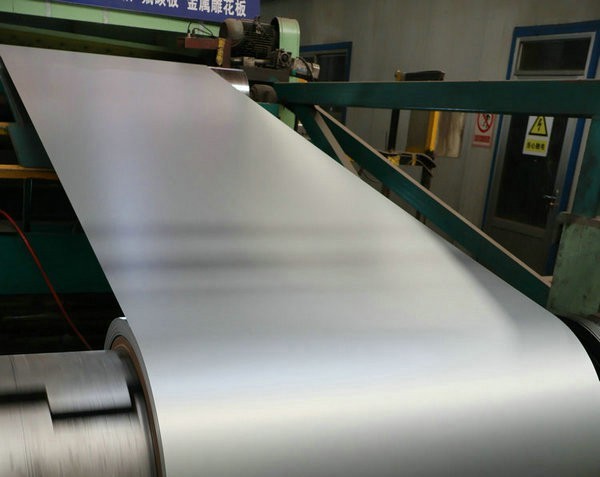

Color-coated aluminum plates are manufactured using continuous roll coating lines, with the primary process flow as follows:

Uncoiling → Pre-degreasing and cleaning → Chemical conversion treatment → Coating application (front and back) → Baking and curing → Cooling → Rewinding → Forming and processing. The entire process employs uninterrupted continuous coating technology, ensuring uniform coating adhesion, stable color, controllable thickness, and maximizing the product's processing performance and decorative effect.

Aluminum's density is only one-third that of steel, significantly reducing structural loads. This facilitates transportation, handling, and installation while enabling the use of large-format plates.

The natural oxide layer on aluminum surfaces forms a self-protective coating. Combined with the protective coating, it maintains stable performance in environments exposed to rainwater, humidity, and acid rain.

It can achieve various surface effects including metallic colors, matte finishes, glossy finishes, wood grain, stone patterns, and brushed metal textures, meeting modern architectural aesthetic trends.

Colored coated aluminum plates exhibit excellent ductility, allowing for cutting, bending, stamping, and rolling without compromising coating adhesion, thus preventing paint loss during fabrication.

Aluminum is 100% recyclable, causing no environmental pollution and meeting sustainable construction requirements.

Many confuse color-coated aluminum plates with color-coated galvanized steel plates, yet significant differences exist:

- Color-coated aluminum plates are lighter, rust-resistant, and offer longer service life;

- Color-coated galvanized steel plates provide higher strength at lower cost;

- Color-coated aluminum plates are recommended for high-humidity, coastal, or highly polluted industrial environments.

In modern buildings, color-coated aluminum plates are commonly used for exterior walls, roofs, curtain walls, and similar components. Their rich colors and diverse textures meet the design demands of various architectural styles. These plates offer excellent weather resistance and corrosion resistance, withstanding variable climates to ensure long-term aesthetic appeal and structural stability. Their lightweight nature also facilitates construction while reducing structural loads.

In transportation, color-coated aluminum plates are widely used for interior and exterior finishes in vehicles such as automobiles, ships, and trains. Their corrosion resistance and wear-resistant properties ensure transport vehicles maintain an excellent appearance across diverse environments. Color coatings can be customized to meet specific design requirements, enhancing the overall visual appeal.

Colored coated aluminum plates are also used for the casings of many home appliances, such as air conditioners, refrigerators, and washing machines. Their ease of forming and processing provides designers with greater creative freedom. Color-coated aluminum coils are frequently used for labels, plates, and other components on industrial equipment to enhance durability and aesthetics.

In billboards, display stands, signage, and similar applications, color-coated aluminum plates are an ideal material choice due to their vivid colors and smooth surfaces. Their weather resistance ensures advertisements maintain their effectiveness outdoors over extended periods without fading or damage.

- Choose PE/SMP/PVDF coating types based on the application environment;

- Verify coating thickness and baking process compliance with standards;

- Recommend PVDF fluorocarbon coating for exterior walls and roofing applications;

- Suggest high corrosion-resistant aluminum-magnesium-manganese alloys for coastal, acid rain, or chemical zones;

- Verify manufacturers possess stable, continuous coating production lines during procurement.

Selecting reputable manufacturers and stable coating systems directly impacts service life and decorative performance.

Driven by rising consumer aesthetic demands for architectural and industrial products, along with diversified material performance requirements, the market for color-coated aluminum plates and coils continues to expand. Technological innovation and environmental policies further propel market evolution.

(1) Continuous Enhancement of Product Performance: Future color-coated aluminum plates will exhibit improved weather resistance, corrosion resistance, and adhesion. New coatings and surface treatment technologies will enhance UV resistance, pollution resistance, and fireproofing properties. For instance, adopting eco-friendly water-based coatings aligns with green development principles while reducing production costs.

(2) Diversified and Personalized Design: With the rise of customization, the color palette and surface textures of color-coated aluminum plates will become more diverse. Beyond traditional solid colors and metallic finishes, gradient hues, textured effects, and patterned prints are gaining popularity. This offers architects and designers greater creative freedom while meeting diverse customer preferences.

(3) Environmental Sustainability: Environmental protection has become a critical global industry focus. The production of color-coated aluminum plates and coils is transitioning toward green, low-carbon practices through the use of eco-friendly coatings, reduced harmful emissions, and increased recycling rates, all driving sustainable development. In the future, green manufacturing and recyclable color-coated aluminum coils will become key market trends.

(4) Technological Innovation: The introduction of automated production lines, digital spraying technology, and intelligent inspection methods has enhanced production efficiency and product quality. Innovative coating technologies enable more efficient color reproduction and enhanced color stability. The application of micro-nano technologies also shows potential in improving surface performance.

(5) Market Expansion: With economic globalization, the market for color-coated aluminum plates and coils is gradually expanding from developed to developing countries. Accelerated infrastructure development and urbanization are creating new growth opportunities for demand. The maturation of regional industrial chains is also promoting product diversification and localized production.

Color-coated aluminum plates combine lightweight properties, corrosion resistance, high strength, and rich decorative options, making them an irreplaceable material in contemporary architecture and metal decoration. Whether pursuing visual expression in modern buildings or considering long-term weather resistance and maintenance costs, color-coated aluminum plates offer solutions that balance economy and performance.

As green building concepts, lightweight construction, and urban facade aesthetics standards continue to evolve, the application scope of color-coated aluminum plates will expand, and their market value will steadily increase. For design firms, construction contractors, and metal processing enterprises, accurately understanding the properties of color-coated aluminum plates and selecting appropriate types will effectively enhance project quality and service life, generating greater economic and social benefits.

China galvanized plate manufacturer: Boxing Shuangshengda Steel specializes in galvanized sheet, galvanized steel plate,Colour steel plate etc.We have a full range of product specifications and types, low prices, and more than 20 years of experience, worthy of your trust