Language

▼

Language

▼

More Language

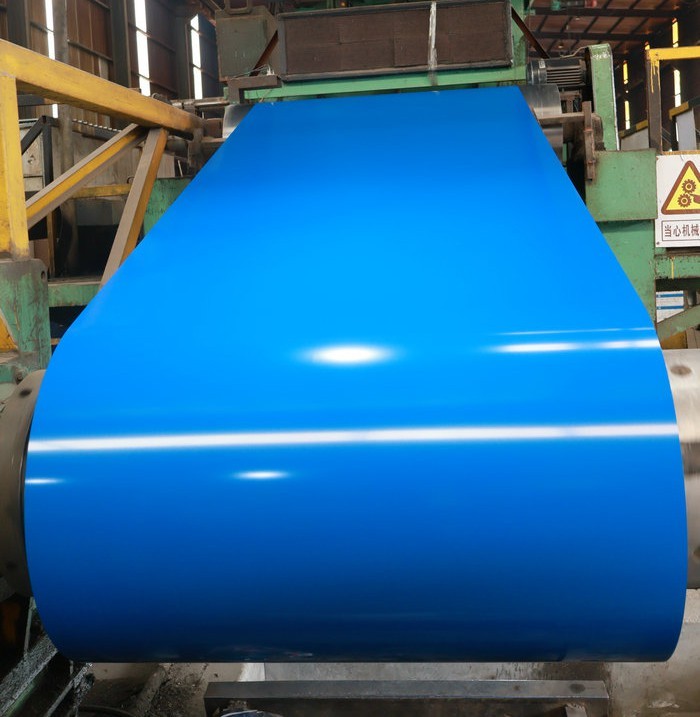

Color-coated steel plates (also known as color steel plates) serve as a vital building and manufacturing material. Due to their excellent corrosion resistance, decorative appeal, lightweight properties, and workability, they are widely used across multiple sectors including construction, home appliances, transportation, and industry. With continuous technological advancements, the production process of color-coated steel plates has matured, extensively replacing traditional materials such as wood, brick, stone, and aluminum alloys. They now play a significant role in numerous fields.

Color-coated steel plates are metal plates manufactured by applying an organic coating to a steel substrate. The coating typically consists of three layers: primer, topcoat, and protective film. The primer enhances adhesion and corrosion resistance, while the topcoat determines the plate's color, gloss, and UV resistance. The protective film serves as a temporary shield against scratches during transportation and processing.

- Core Advantages of Color-Coated Steel Plates Include:

(1) Superior Corrosion Resistance: The coating offers excellent anti-corrosion properties, effectively resisting erosion from natural environmental factors such as acid rain, humidity, and UV radiation.

(2) Strong Decorative Appeal: Customizable in various colors and patterns to meet client needs, it can even simulate wood grain, stone texture, and other effects, making it widely used in architectural decoration and home appliance design.

(3) Lightweight yet strong: Compared to traditional materials, color-coated steel plates are lighter in weight but possess sufficient strength to meet various engineering requirements.

(4) High workability: They can undergo multiple processing methods such as curling, bending, and shearing, facilitating construction and usage.

Leveraging their unique properties, color-coated steel plates are widely used across multiple industries, particularly in construction, home appliances, transportation, and industrial sectors.

The most extensive application of color-coated steel plates in construction is reflected in the following areas:

- Roofing and Wall Cladding: Commonly used for roofs and walls in industrial plants, warehouses, and commercial buildings, providing waterproofing, corrosion resistance, and wind resistance. Compared to traditional materials, color-coated steel plates are lighter, easier to install, and offer a wide range of colors to enhance building aesthetics.

- Light Steel Frame Construction: Color-coated steel plates are a common material in light steel frame buildings, extensively used for exterior walls and roofs in structures like office buildings, exhibition halls, and sports arenas.

- Portable Buildings and Modular Construction: Beyond conventional buildings, color-coated steel plates are employed in modular structures and portable buildings such as temporary housing, offices, and restrooms. These buildings offer high mobility, ease of disassembly, and excellent durability.

Color-coated steel plates are extensively used in the home appliance industry, primarily for manufacturing appliance casings. Their excellent workability and decorative properties make them the preferred material for appliance exteriors. Common applications include:

- Refrigerator, air conditioner, and washing machine casings: Color-coated steel plates provide excellent corrosion resistance and durability for appliance exteriors, withstanding environmental exposure while maintaining an attractive appearance.

- Microwave ovens and conventional ovens: These plates are extensively used in kitchen appliances, their high heat resistance enabling operation in high-temperature environments.

Color-coated steel plates are extensively applied in the transportation sector, primarily in the following areas:

- Automotive Manufacturing: Widely used in the automotive industry, particularly for producing body plates and chassis components. These plates provide the structural strength required for vehicles while effectively preventing body corrosion and enhancing durability.

- Trucks and Containers: Color-coated steel plates are extensively used in truck bodies, container interiors, and other logistics facilities. Their corrosion resistance and lightweight properties make them indispensable materials in the transportation sector.

- Shipbuilding: Color-coated steel plates are employed in the hulls and structural components of certain vessels, effectively preventing seawater corrosion while offering robust resistance to wind and waves.

Applications of color-coated steel plates in industrial manufacturing primarily include machinery, enclosures, and household goods:

- Cabinets and Enclosures: Widely used in housings, cabinets, and control plates for various machinery, offering strong corrosion resistance and an aesthetically pleasing appearance.

- Industrial Equipment Guards: In numerous industrial applications, color-coated steel plates serve as external protective covers or shielding plates, effectively shielding equipment from environmental damage.

- Steel Furniture: Color-coated steel plates are utilized in manufacturing diverse steel furniture items, including desks, filing cabinets, and storage units.

Color-coated steel plates are also widely used in agriculture and livestock, particularly in construction and equipment manufacturing:

- Agricultural Greenhouses: In agriculture, color-coated steel plates are commonly used as wall and roof materials for greenhouses. Their corrosion resistance and light transmission properties create optimal environmental conditions, helping to increase crop yields.

- Livestock Equipment: In animal husbandry, color-coated steel plates are used to construct facilities such as pigsties, cattle sheds, and chicken coops. These structures resist environmental impacts, offer high durability, and create favorable breeding environments.

Beyond industrial and construction applications, color-coated steel plates play an increasingly vital role in home furnishings and decoration:

- Ceiling and Interior Decoration: With their rich colors and strong decorative appeal, color-coated steel plates are commonly used as decorative materials for ceilings, walls, and floors in commercial buildings, residential spaces, and entertainment venues.

- Commercial Display Facilities: Color-coated steel plates can be used to create exhibition stands, billboards, display racks, etc. Their vibrant colors and flexible designs effectively attract customer attention.

With the continuous development of global construction and manufacturing industries, the market demand for color-coated steel plates continues to grow. Particularly in the areas of new building materials and environmental protection/energy efficiency, color-coated steel plates are increasingly favored by the market due to their advantages such as light weight, energy efficiency, and environmental friendliness. In the future, the market outlook for color-coated steel plates will remain positive, primarily reflected in the following aspects:

(1) Application of Green and Eco-Friendly Materials: As global environmental standards rise, the eco-friendliness of color-coated steel plates will become a key trend for future development. Developing low-VOC, non-toxic, and recyclable coating systems will become a key direction for future production.

(2) Personalized Design Demands: As consumer expectations for customization and individuality increase, the design of color-coated steel plates will diversify to meet the specific needs of different industries and users.

(3) Intelligent Manufacturing: Future production processes will become more intelligent, utilizing digital control systems to enhance efficiency, improve product quality, reduce resource waste, and increase output value.

As a multifunctional, eco-friendly, aesthetically pleasing, and highly efficient building and manufacturing material, color-coated steel plates have become an indispensable component of modern manufacturing through their extensive applications across construction, home appliances, transportation, and industrial sectors. With continuous technological advancements and evolving market demands, the functionalities and application domains of color-coated steel plates will continue to expand, injecting new vitality into the industry's development.

China galvanized plate manufacturer: Boxing Shuangshengda Steel specializes in galvanized sheet, galvanized steel plate,Colour steel plate etc.We have a full range of product specifications and types, low prices, and more than 20 years of experience, worthy of your trust