Language

▼

Language

▼

More Language

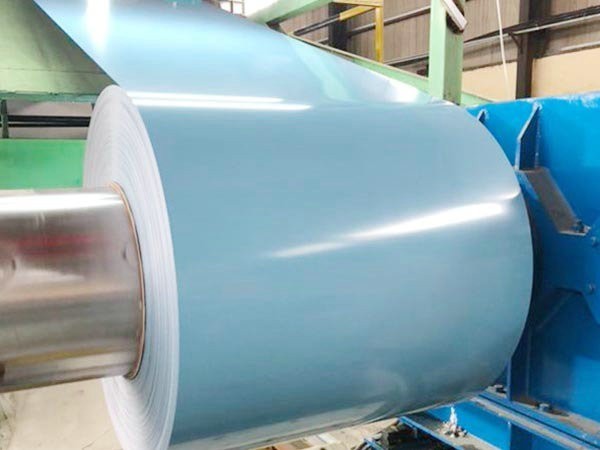

In the architectural decoration and metal processing industries, a new type of material that is both aesthetically pleasing and durable—coloured aluminium plate—is rapidly gaining market share. We often encounter coloured aluminium panels in our daily lives, but many people are not very familiar with this metal material. We will provide a comprehensive analysis of this metal material that combines decorative and functional properties.

Coloured aluminium sheets, as the name suggests, are aluminium sheets coated with an organic coating and cured at high temperatures to form a new type of environmentally friendly coating material.

Coloured aluminium sheets combine aesthetics with durability. After being processed through a coloured coating system, their surfaces are covered with one or more layers of organic coatings, which are then baked and cured to form a composite material. This material not only offers a rich variety of colours but also boasts excellent weather resistance and corrosion resistance. After special surface treatment, it ensures at least eight years of colour retention. Additionally, it has low density and high hardness, making it the lightest metal material per unit volume.Colour-coated aluminium sheets are cured through baking to form a composite material, with options for polyester coating or fluorocarbon coating. The former offers excellent UV resistance, while the latter provides superior weather resistance, making it particularly suitable for interior and exterior decoration in public spaces, commercial chains, exhibition advertising, and other decorative and display applications.

One of the significant advantages of coloured aluminium sheets is their rich colour options, which can be customised according to customer requirements. Compared to traditional painted sheets, coloured aluminium sheets have more vibrant and stable colours that are less prone to fading and deformation. These advantages make coloured aluminium sheets widely used in architectural decoration, billboards, and interior decoration.

Coloured aluminium panels are treated with a special coating, giving them outstanding corrosion resistance. Even in humid environments, they are less prone to rusting and corrosion. As a result, coloured aluminium panels are more durable and have a longer service life than traditional iron panels or painted panels.

Due to their excellent corrosion resistance and colour stability, coloured aluminium sheets have a significantly longer service life than ordinary iron sheets or painted sheets. Under normal conditions, coloured aluminium sheets can be used for over 20 years without showing significant signs of ageing.

The surface of coloured aluminium sheets is extremely smooth and has strong adhesive properties, enabling them to bond well with building materials such as plaster and cement. As a result, they are widely used in architectural decoration, interior design, and other fields. Additionally, the surface material of coloured aluminium sheets is extremely hard, resistant to scratches and deformation, and has a longer service life.

The coloured coating film is made from imported raw materials and does not contain formaldehyde or other harmful substances, making it harmless to humans and compliant with national environmental protection standards.

It can be cut and adjusted to different widths and thicknesses to meet various requirements, and can be installed using either exposed or concealed mounting methods, making it convenient and efficient.

Due to their unique properties and decorative effects, colour-coated aluminium panels are widely used in multiple fields:

(1) Construction industry: Colour-coated aluminium can be used for building exteriors, roofs, doors, and windows, enhancing the aesthetic appeal and durability of buildings. Additionally, colour-coated aluminium can be used to manufacture construction templates, scaffolding, and other construction facilities, improving construction efficiency.

(2) Home decoration industry: Coloured aluminium can be used to make furniture, cabinets, bathroom fixtures, and other home products, adding a sense of fashion and modernity to the home environment. Additionally, coloured aluminium can be used in home decoration for ceilings, partitions, and other areas to enhance the decoration effect.

(3) Transportation industry: Coloured aluminium can be used to make the bodies and components of vehicles such as cars, trains, and airplanes, reducing weight and improving operational efficiency and safety.

(4) Other fields: Coloured aluminium can also be applied in fields such as electronic products, packaging materials, and advertising, leveraging its lightweight, aesthetic, and durable characteristics.

When selecting coloured aluminium sheets, the following factors should be considered:

- Coating type: Fluorocarbon coatings are suitable for long-term outdoor use, offering better weather resistance than polyester coatings, but at a higher cost; polyester coatings

is suitable for indoor or short-term outdoor use, offering better cost-effectiveness.

- Thickness specifications: The thickness of coloured aluminium sheets typically ranges from 0.2mm to 3mm. Thicker sheets have higher strength and impact resistance but are more expensive; selection should be based on usage requirements.

- Colour and texture: Select surface finishes such as matte, glossy, or wood grain patterns according to design requirements.

-Manufacturers: Select reputable manufacturers with stable quality and comprehensive after-sales service to ensure product quality and delivery schedules.

Advantages:

Lightweight and Durable: Coloured aluminium panels are lightweight but have high strength and hardness, capable of withstanding significant pressure and loads, and offer excellent durability.

Rich Colours: Coloured aluminium panels come in a variety of colours to meet different user needs, and their colours remain vibrant over time.

Easy Installation: Coloured aluminium panels are simple and convenient to install, supporting both dry and wet construction methods, significantly reducing construction difficulty and costs.

Disadvantages:

Relatively high cost: Compared to ordinary metal panels, coloured aluminium panels are slightly more expensive, but their durability and low maintenance costs can offset part of the initial investment over the long term.

Although coloured aluminium panels have good weather resistance, proper maintenance can further extend their service life:

- Regular cleaning: Wipe the surface with clean water or a neutral cleaner, avoiding the use of strong acid or alkali cleaners.

- Inspect fasteners: After prolonged use, check whether screws, rivets, and other connecting components are loose, and reinforce them promptly.

- Avoid scratches from hard objects: Protect the surface coating during handling or installation to prevent scratches.

Coloured aluminium panels excel in environmental performance:

- Recyclable: Aluminium alloy can be recycled multiple times, reducing resource waste.

- Low-pollution production process: Modern coating technologies have significantly reduced the use of harmful substances, making the production process more environmentally friendly.

Colour-coated aluminium panels are a new type of building material that is aesthetically pleasing, reliable in quality, and environmentally friendly. They are widely used in building facades, roofs, ceilings, and electrical equipment enclosures. In the future, as society continues to develop, the application scope of colour-coated aluminium panels will become even broader, and their market prospects will be even more promising.

China galvanized plate manufacturer: Boxing Shuangshengda Steel specializes in galvanized sheet, galvanized steel plate,Colour steel plate etc.We have a full range of product specifications and types, low prices, and more than 20 years of experience, worthy of your trust