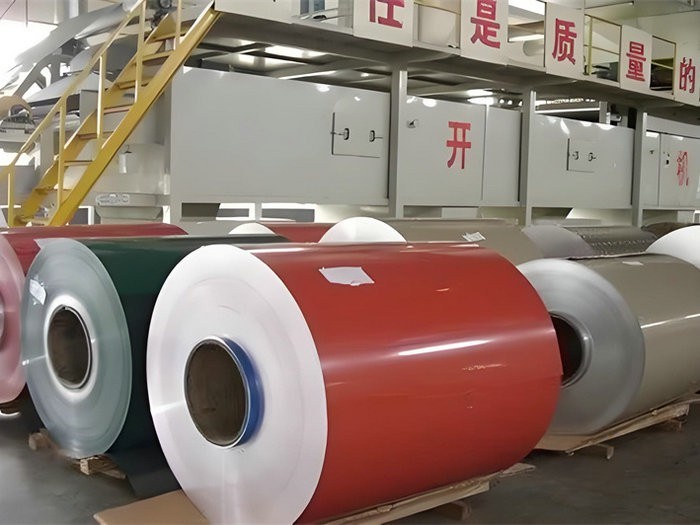

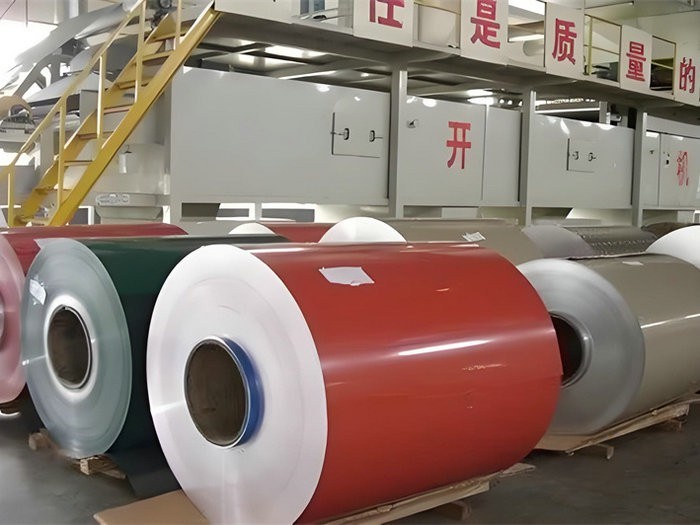

Color steel plate, as a commonly used building material, is widely used in all kinds of construction projects because of its advantages of light weight, high strength, rich color and convenient construction. However, to ensure the service life and performance of color steel plate, it is vital to do a good job of daily maintenance. The following will introduce the points of daily maintenance of color steel plate in detail.

1. Regular cleaning

- Surface dust cleanup: the surface of color steel plate is easy to adsorb dust and impurities, these dust if accumulated for a long time, will not only affect the appearance of the color steel plate, but also may be in the humid environment and moisture combination, the formation of dirt, and then corrosion of the surface of the color steel plate. Therefore, it should use soft cloth or cleaning tool regularly to wipe the surface of color steel plate. It is generally recommended to carry out the cleaning of surface dust at least once a month. When wiping, pay attention to moderate strength, avoid scratching color steel plate surface coating.

- Special stains treatment: If the surface of color steel plate has oil stains, rust stains and other special stains, you need to use a special cleaner to deal with. For oil stains, you can use mild neutral cleaner, dilute the cleaner, dip a soft cloth into the solution and gently wipe the oil stained parts until the oil stain is removed. Then rinse well with water and dry the surface. For rust, use a rust remover, but you need to test it on a small area before using it to make sure that the rust remover will not damage the surface coating of the color steel plate. After removing the rust, the surface should be cleaned and dried likewise.

2. Check the connection parts

- Bolt and rivet: Color steel plate is usually installed and fixed by bolts, rivets and other connecting parts. In the daily maintenance, it is necessary to regularly check whether these connecting parts are loose. Tools such as wrenches can be used to tighten the bolts to ensure that they are firmly connected. For rivets, it is necessary to check whether there is any loosening or falling off. If the rivets are found to be loose or fall off, they should be replaced in time to prevent displacement, deformation and other problems of the color steel plate. Generally, a comprehensive inspection should be carried out on the connection part every quarter.

- Sealing tape: The splicing place of color steel plate usually uses sealing tape to prevent rainwater, dust and so on from entering. It is necessary to check whether the sealing tape is in good condition, whether there is aging and broken phenomenon. If the sealing tape is aging or broken, it should be replaced with new sealing tape in time to ensure the sealing performance of color steel plate. The inspection of sealing tape can be carried out together with the inspection of connection parts.

3. Pay attention to coating condition

- Coating wear: The coating of color steel plate has the function of protecting steel plate and beauty. In daily use, pay attention to whether the coating is worn or scratched. If the coating is found to be slightly worn, it can be repaired with repair paint of similar color to the coating of color steel plate. Before repairing, the surface of the worn area should be cleaned up first to remove dust, oil and other impurities, and then applied according to the instructions for the use of repair paint. For areas with more severe coating wear, it is recommended to contact a professional.

- Coating chalking: When exposed to sunlight and harsh environment for a long time, the coating of color steel plate may appear chalking phenomenon. When powdery substances are found on the surface of the coating, it indicates that the coating has begun to chalk. At this time, it is necessary to clean up the chalking area in time and consider whether it is necessary to re-coating treatment according to the actual situation. Regularly check the coating condition of the color steel plate, generally every six months for a comprehensive inspection, in order to timely find problems and take measures.

4. Preventing external impact

- Peripheral operation pay attention to: when carry out other construction or operation around the color steel plate building, we should pay special attention to prevent the external force from hitting the color steel plate. For example, when carrying out overhead work, lifting and transporting articles and other operations, necessary protective measures should be taken, such as setting up warning signs, building protective sheds and so on, to avoid construction tools, materials and so on hitting the color steel plate. If in the course of operation accidentally hit the color steel plate, to timely check whether the color steel plate is damaged, such as deformation, breakage and other cases, to repair in time.

- Daily maintenance operation specification: In the daily cleaning, checking and other maintenance operation of the color steel plate, also pay attention to avoid using sharp, hard tools, so as not to cause scratches or impact damage to the color steel plate. The operator walks or works on the color steel plate, should pay attention to the safety of the feet, avoiding damage to the color steel plate due to slipping, collision and other reasons.

5. Do waterproof drainage

- Roof drainage check: for color steel plate roof, should regularly check whether the drainage system is smooth. Check whether the drainage slope of the roof meets the design requirements, whether the drainage outlet is blocked by debris. If the drainage outlet is found to be blocked, the debris should be cleared in time to ensure smooth drainage. Before the rainy season, the roof drainage system should be comprehensively inspected and maintained to prevent rainwater from accumulating on the roof and causing soaking and corrosion to the color steel plate.

- Waterproof treatment of wall surface: the bottom and edge parts of color steel plate wall surface are prone to rainwater seepage and leakage. It is necessary to check whether the waterproof sealing of these parts is good or not, if there are gaps or holes, sealing treatment should be carried out in time. Waterproof sealant can be used to seal the gaps to prevent rainwater from seeping into the interior of the wall. At the same time, it is important to keep the ground around the wall draining freely to avoid erosion of the bottom of the wall caused by stagnant water.

6. Coping with bad weather

- Strong wind weather: Before the strong wind weather comes, it is necessary to carry out a comprehensive inspection of the color steel plate building and reinforce the parts that may be loose, such as checking whether the doors and windows are closed firmly and fastening the connection parts of the color steel plate again. After the strong wind, we should check whether the color steel plate has deformation, displacement and so on, if there is damage, we should repair in time.

- Rainstorm, snowstorm weather: heavy rain and snowstorm weather may cause color steel plate roof to bear greater pressure. During heavy rain and snowstorms, pay close attention to the situation of the roof, and take drainage and snow removal measures in time if there is too much water or snow. Avoid long time accumulation of water or snow on color steel plate cause excessive pressure, lead to deformation or damage.

The advantage of color steel plate is not only embodied in the installation stage, but also embodied in the reliability of long-term use. And the foundation of reliability is exactly the scientific daily maintenance. Through regular cleaning, fastening check, coating repair, waterproofing and bad weather response, the service life of color steel plate can be extended to the maximum extent and the maintenance cost can be reduced in the later stage.

With the promotion of green building and sustainable development, the demand of color steel plate will continue to grow. For users, learning to properly maintain color steel plate can not only guarantee the safety and beauty of the building, but also reflect the professionalism and responsibility.

Language

▼

Language

▼