Language

▼

Language

▼

More Language

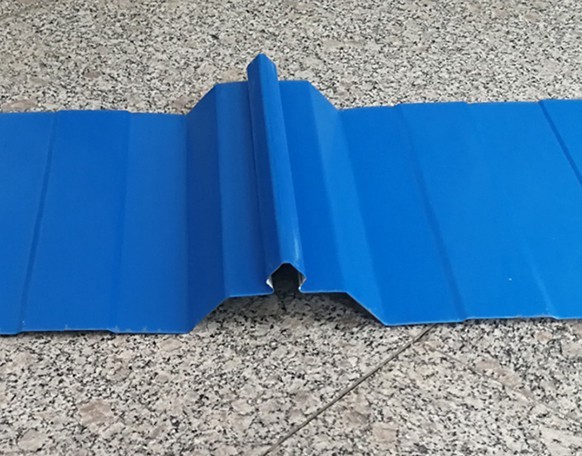

Color steel tiles, as a widely used wall material in modern construction, are favored for their lightweight, diverse colors, easy installation, and high cost-effectiveness. However, due to their year-round exposure outdoors and prolonged exposure to acidic and alkaline substances, their surfaces inevitably accumulate dirt such as dust deposits, oil stains, rust spots, and even moss. These contaminants not only compromise the building's overall aesthetics but may also accelerate the aging of the coating, shortening its service life.

Therefore, regular cleaning and maintenance of color steel tiles are crucial. Proper, scientific cleaning methods can restore the tiles' original vibrant appearance while effectively extending their lifespan and reducing repair and replacement costs.

A building's exterior appearance directly impacts the image of a business or individual. Color steel tile exposed to prolonged wind and sun, covered in dust, rust stains, or spots, not only diminishes visual appeal but may also convey an impression of poor management.

The coating on color steel tiles is crucial for corrosion and rust prevention. Once covered by contaminants or corroded, it exposes the steel substrate to air, accelerating rust formation. Regular cleaning prevents long-term buildup of corrosive substances, preserving the coating's protective function.

Accumulated debris or standing water on some roof panels can increase load pressure, potentially causing leaks or collapses during extreme weather. Timely cleaning mitigates these risks, safeguarding both the structure and occupants.

With the growing emphasis on green building practices, regular cleaning and maintenance of color steel tiles aligns with modern building management requirements for energy efficiency, environmental protection, and sustainable development.

Color steel tile offers excellent thermal insulation properties, primarily manifested in the following aspects:

- Featuring a double-layer or multi-layer structure, the interlayer can be filled with insulation materials such as EPS, PU, or rock wool. This prevents indoor temperature loss in winter and heat gain in summer, ensuring comfortable indoor temperatures.

- The tiles maintain thermal integrity even in environments reaching 60°C (120°F), without significant temperature differentials.

Fabricated from color steel tiles, these tiles combine aesthetic appeal with robust fireproofing. Typically rated B1 or higher, they significantly reduce fire risks, safeguarding lives and property.

Fabricated from premium steel and treated with coatings during production, color steel tiles feature a smooth surface with corrosion resistance, waterproofing, wind resistance, and acid/alkali tolerance. After years of use, they exhibit no signs of aging, peeling, or cracking, ensuring a long service life with low maintenance costs.

Chemical cleaning utilizes specific chemical agents that react with dirt and rust stains to achieve removal.

- Foam Cleaner: Suitable for dust and light stains on large surfaces. Apply the cleaner to the tile surface, let it sit briefly, then rinse with water. Avoid scrubbing with hard objects.

- Alkaline Cleaners (e.g., sodium hydroxide solution): Primarily used for oil and grease stains. Dilute strictly according to the specified ratio before use to prevent coating damage from excessive alkaline concentration.

- Acidic Cleaners (e.g., diluted acid wash): Used for removing stubborn rust spots and oxide scale. Always wear protective gloves and goggles during use. Rinse thoroughly with copious amounts of water after cleaning to prevent residual corrosion.

Chemical cleaning is suitable for heavily contaminated areas but requires strict adherence to safety protocols and dilution ratios.

High-pressure water guns or pressure washers are common tools for cleaning color-coated steel sheets, suitable for rapid cleaning of large roof areas.

- Pressure adjustment: Maintain moderate water pressure; excessive pressure may impact the coating, causing paint peeling or scratches.

- Nozzle angle: Maintain a slight angle relative to the steel sheet to avoid direct vertical high-pressure impact.

- Operating Distance: Maintain a 30-50 cm distance between the nozzle and the panels to balance cleaning effectiveness and safety.

This method is highly efficient and water-saving, suitable for regular maintenance.

For localized contamination or detailed cleaning, manual scrubbing is more reliable.

- Use soft-bristle brushes, sponges, or cotton cloths with mild detergents to gently wipe surface stains.

- Avoid steel wool pads or hard-bristle brushes to prevent coating damage.

- Rinse thoroughly with clean water immediately after cleaning to remove all detergent residue.

For surfaces with mild rust spots, apply specialized rust remover.

- Apply rust remover to affected areas, let sit for 5-10 minutes, then rinse with clean water.

- For heavily rusted areas, lightly sand before applying rust inhibitor, then touch up with repair paint after drying.

In recent years, large factories or warehouses increasingly utilize specialized roof cleaning equipment, such as:

- Rotary brush cleaners: Combine high-pressure water jets with rotating brush heads to efficiently remove stubborn grime.

- Vacuum-type cleaning equipment: Suitable for dusty environments where water usage is restricted.

These devices offer high operational efficiency but require professional operation and maintenance.

Confirm the presence of severe cracks, loose sections, or detached areas on the roofing. Develop a cleaning plan based on actual conditions.

Divide large roof areas into sections for cleaning to prevent omissions or redundant work.

Clean from the highest to lowest points of the roof to allow wastewater to drain naturally.

Ensure all cleaning agents and stains are completely rinsed away to prevent secondary contamination from residues.

Inspect surfaces for damage post-cleaning and repair immediately if necessary.

Refrain from using concentrated acids, alkalis, or similar agents to prevent damage to color steel tile surfaces.

When working at heights, always wear safety harnesses and slip-resistant footwear. Avoid cleaning during rain or high winds.

Collect waste liquid centrally; avoid direct discharge into the natural environment.

Generally, cleaning 1-2 times per year is sufficient; avoid excessive frequency that may cause coating wear.

If localized paint loss is found after cleaning, promptly apply specialized touch-up paint to prevent rust spread.

In humid, rainy, or coastal regions, apply rust-proof paint or protective coatings to color steel roofing panels every 2-3 years.

Establish a maintenance log for color steel panels, conducting quarterly inspections to document cleaning and repair activities.

Regularly clean roof gutters and downspouts to prevent water accumulation from soaking the panels.

In summary, cleaning color steel tiles is a critical maintenance task that goes beyond mere “surface work.” It directly impacts the safety of the roof structure and the overall lifespan of the building, while also addressing safety and environmental concerns. Through “regular cleaning + timely maintenance,” not only can the building's appearance be kept neat and aesthetically pleasing, but the service life of the color steel tiles can also be extended, reducing overall maintenance costs and delivering tangible economic and social benefits for both businesses and users.

China galvanized plate manufacturer: Boxing Shuangshengda Steel specializes in galvanized sheet, galvanized steel plate,Colour steel plate etc.We have a full range of product specifications and types, low prices, and more than 20 years of experience, worthy of your trust