Language

▼

Language

▼

More Language

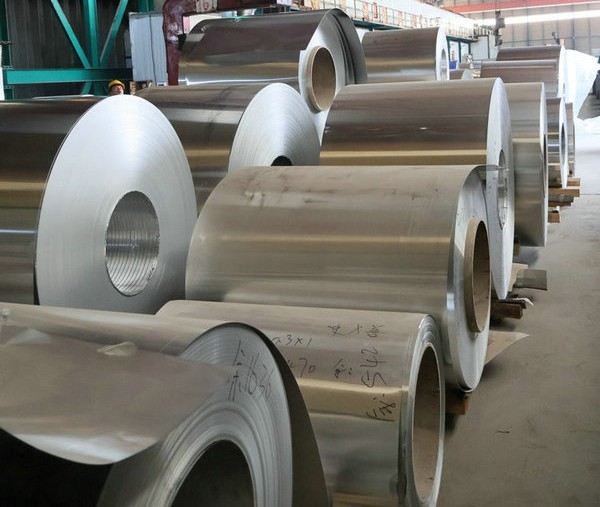

The transportation link is crucial in the production and sales chain of color coated rolls. Color coated rolls, as a composite material that perfectly combines the mechanical properties of metals with the decorative, weather resistant, and corrosion-resistant properties of coatings, are widely used in many fields such as construction, home appliances, and transportation. However, various uncertain factors during transportation, such as collision, compression, environmental changes, etc., may cause varying degrees of damage to the color coated roll, thereby affecting its quality and subsequent use. Therefore, exploring how color coated roll manufacturers can avoid damage during transportation is of great practical significance.

Prevention is better than cure, and adequate preparation is the first line of defense to ensure transportation safety.

-Vehicle condition inspection: Ensure that the vehicle surface is flat, clean, and free of any protrusions, oil stains, or chemical residues. Check whether the vehicle saddle (V-frame or cross frame) is intact, whether the rubber or wooden material of the pad is worn or hardened, and ensure that it can effectively prevent slipping and cushion.

-Check the shipping order to ensure that the loading sequence matches the unloading sequence, avoiding repeated movement during the process due to searching for goods.

Loading is the most vulnerable stage during transportation, and standardized operations must be carried out.

-Smooth operation: The lifting process should be smooth and slow, avoiding sudden stops and starts, and preventing the coil from hitting hard objects due to inertial shaking. It is strictly prohibited to thread steel pipes through the coil material.

-Multiple bundling fixation: Cross bundling is carried out in the radial (circumferential) and axial (width) directions to firmly fix the roll material to the vehicle. Effective corner protectors or cushioning pads must be added at the contact point between the strapping and the surface of the color coated roll to prevent stress concentration from cutting or crushing the coating.

After the vehicle is started, risk management does not end, but enters the dynamic monitoring phase.

-Drivers should maintain smooth driving at medium and low speeds, avoid sudden braking and sharp turns, and minimize the movement and impact of cargo caused by inertia.

-In case of sudden rainfall, the waterproof cover should be checked immediately to ensure that the color coated roll is not wet.

Table: Overview of transportation risk points and corresponding protective measures for color coated rolls

|

Risk Category |

Specific Risk Points |

Core Protective Measures |

|

Physical Damage |

Edge磕碰 (Edge bumps), Friction between rolls, Surface scratches |

Use high-strength corner protectors, Fill gap materials, Use special lifting straps, Add buffer pads at contact points |

|

Chemical Corrosion |

Rainwater, Seawater, Moisture, Pollutant erosion |

Adopt moisture-proof and waterproof packaging (Vacuum/film + desiccant), Avoid polluted environments, Store indoors |

|

Deformation and Instability |

Roll deformation, Cargo shifting, Strapping failure |

Insist on vertical placement, Balance the load, Use multiple cross-strapping for fixation, Drive smoothly |

|

Operational Errors |

Improper lifting, Rough handling, Incorrect tools |

Use special nylon lifting straps, Standardize lifting operations, Train operating personnel, Prohibit horizontal placement |

3. Standardized storage: After confirming that there are no errors, the color coated rolls should be transferred to the final indoor storage location as soon as possible and continue to be stored vertically to complete the closed-loop management of the entire transportation process.

China galvanized plate manufacturer: Boxing Shuangshengda Steel specializes in galvanized sheet, galvanized steel plate,Colour steel plate etc.We have a full range of product specifications and types, low prices, and more than 20 years of experience, worthy of your trust