Language

▼

Language

▼

More Language

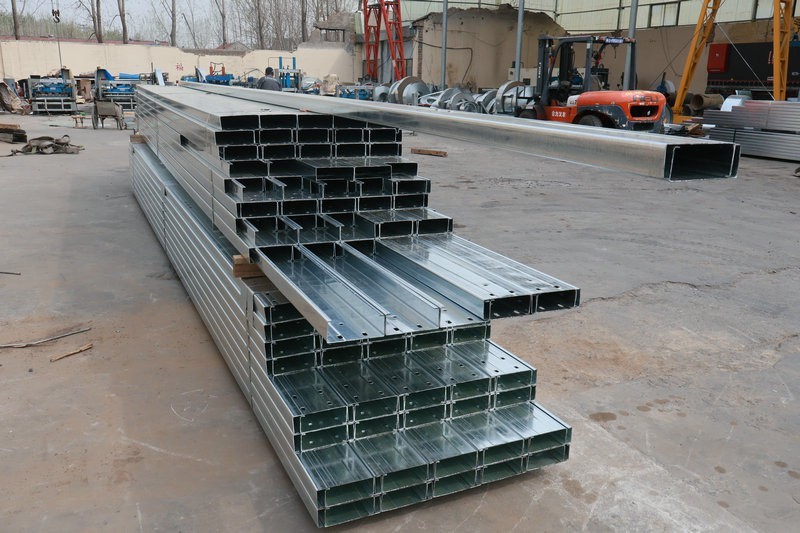

A C-shaped steel section, in simple terms, is a cross-sectional shape made of steel through cold bending forming technology. Its outer contour resembles the English letter "C", and is formed by a steel plate that is cold bent by a machine to form a unique structure with parallel upper and lower flanges and inward curled edges. This cross-sectional design cleverly integrates mechanical principles, and the rolled edge not only enhances the torsional stiffness of the structure, but also effectively disperses stress, making customize C-shaped steel perform well under vertical and horizontal loads. Compared to traditional hot-rolled steel, C-shaped steel has a thinner and lighter cross-section, but can provide higher bending and shear resistance under the same weight. At the same time, due to its high material utilization and convenient processing, it has become an indispensable structural material in fields such as construction, machinery, and vehicle manufacturing. From lightweight steel frames in industrial plants to shelving systems in logistics and warehousing, C-shaped steel sections are constantly expanding their application boundaries due to their economy and adaptability, becoming a typical representative of "small sections, big achievements" in modern engineering.

It should be distinguished that C-shaped steel is different from similar channel steel. The inner wall of the flange of traditional hot-rolled channel steel has a certain slope, and the flange is relatively thick without a rolled edge at the end. C-shaped steel is usually produced through cold bending forming process, with relatively uniform and thin wall thickness, and distinctive rolled edges. Therefore, C-shaped steel is also known as "cold-formed rolled edge channel steel" or "C-shaped purlin", which accurately summarizes its manufacturing process and core applications.

The reason why C-shaped steel has become a darling in the engineering field is due to its excellent mechanical properties and comprehensive economic advantages brought by its cross-sectional shape.

This is the most prominent advantage of C-shaped steel. Its C-shaped open cross-section belongs to the category of "efficient cross-section" in material mechanics. It distributes materials as far away from the central axis (neutral axis) of the cross-section as possible, thereby obtaining the maximum moment of inertia of the cross-section with the least amount of material. This means that when subjected to bending loads, C-shaped steel can exhibit extremely high bending resistance while being lightweight. This not only saves material costs, but also reduces the requirements for supporting structures, facilitating transportation and installation.

As mentioned earlier, rolled edges are the soul design of C-shaped steel. Thin walled components are prone to local instability under pressure, resulting in wavy distortion of the flanges or web plates. Curling provides a strong boundary constraint for the flange, as if adding a "reinforcing rib", significantly increasing the critical buckling stress of the flange and ensuring that the section does not experience local failure before reaching the overall yield strength.

The geometric shape of C-shaped steel makes it very easy to process and connect. Its flat flange provides an ideal platform for bolted connections, welding, or other fastening methods. In architecture, it can be easily assembled with C-shaped steel or other components of the same cross-section (such as square steel pipes, H-beams) through connectors to form a stable frame system. In addition, it is also easy to cut, drill, and cold bend to meet different design requirements.

Cold bending forming process is an efficient continuous production process with extremely low material loss and high production efficiency, which makes the cost of C-shaped steel relatively low. Meanwhile, its lightweight and high-strength characteristics mean that less steel is used while achieving the same structural performance, thereby reducing the overall project cost. In terms of design, different thicknesses and sizes of C-shaped steel can be flexibly selected according to the stress conditions of different parts, achieving precise material configuration and avoiding waste.

The production of C-shaped steel strictly follows national standards, with precise dimensions and stable quality. This lays the foundation for modular design and prefabricated construction, greatly improving engineering efficiency and quality controllability.

The advantages of cold bending technology lie in its fast speed, low energy consumption, good surface quality (able to retain the galvanized layer or color coating), and the ability to easily adjust the cross-sectional size by replacing the rolling mill, achieving production flexibility.

With the above advantages, customize C-shaped steel is widely used in various industries.

-Building decoration and partitions: can be used for vertical keels of suspended ceilings, lightweight partition walls, etc., with convenient construction and sturdy structure.

-Shelves and storage systems: The beams and columns of heavy-duty shelves are sometimes made of specially designed thick walled C-shaped steel to carry the weight of large goods.

-Auxiliary structures of bridges: Customized C-shaped steel can also be used in some secondary structures such as maintenance channels and guardrails of bridges.

China galvanized plate manufacturer: Boxing Shuangshengda Steel specializes in galvanized sheet, galvanized steel plate,Colour steel plate etc.We have a full range of product specifications and types, low prices, and more than 20 years of experience, worthy of your trust