Language

▼

Language

▼

More Language

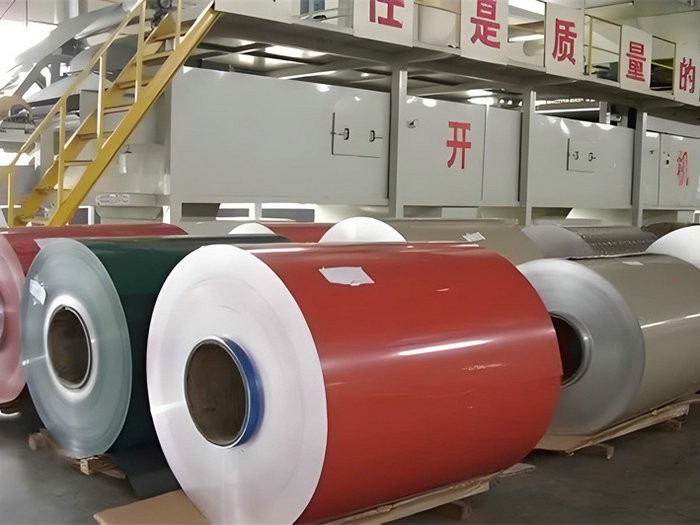

Color steel plates are widely used in various buildings, warehouses, factories, residences, and other facilities due to their lightweight, high strength, corrosion resistance, and rich color options. Whether serving as roofing material or wall cladding, color steel plates provide superior protection. However, to ensure their performance and appearance remain unaffected during long-term use, proper daily maintenance is crucial. This article details routine maintenance methods for color steel plates, helping extend their service life while preserving functionality and aesthetics.

Color steel plate surfaces readily accumulate dust, stains, and contaminants. Regular cleaning not only maintains appearance but also prevents surface coatings from corroding due to dirt or pollutants, thereby extending longevity.

(1) Surface Dust Removal:Dust and grime often accumulate on the surface of color steel plates, which not only affects their appearance but may also hinder their normal functionality. When cleaning color steel plates, it is recommended to use a soft broom, feather duster, or slightly damp cloth to gently remove dust. For high or hard-to-reach areas, use long-handled cleaning tools or specialized cleaning equipment. Cleaning should be performed monthly to ensure the surface remains clean. Simple dust removal is sufficient when no significant stains are present.

(2) Stain Treatment:If oil stains, water marks, or other stubborn stains appear on the surface, prompt cleaning is necessary. Mix a mild detergent (such as dish soap) with water at a ratio of 1:10. Dip a soft cloth into the solution and wipe the stained area. Avoid using abrasive tools like steel wool or sandpaper to prevent coating damage. For stubborn stains, increase the detergent concentration. After cleaning, thoroughly rinse the solution with clean water to prevent residual detergent from causing further corrosion.

The structural integrity of color steel plates directly impacts their long-term stability and safety. Therefore, regularly inspecting connection points and plate deformation is crucial.

Color steel plates are typically installed using fasteners like screws and rivets. Ensuring the security of these connection points is paramount. Regularly inspect these fasteners for loosening or damage. Use a screwdriver to check screw tightness and verify rivets remain intact without detachment. Tighten loose screws or replace damaged fasteners promptly. Conduct comprehensive quarterly inspections, with special attention to connection points after severe weather events like strong winds or heavy rain.

During use, color steel plates may develop surface deformations such as dents, bulges, or bending due to external forces. Regularly inspect the plate surfaces for any deformation. For minor warping, attempt correction using specialized tools. However, if deformation is severe, replace the plate to prevent compromising structural stability and sealing integrity. To ensure overall structural safety, routinely inspect the shape and appearance of the color steel plates.

The coating serves as a critical protective layer for color steel plates, effectively preventing oxidation, corrosion, and enhancing appearance. Regular inspection and repair of the coating are essential for maintaining the plate's performance.

(1) Coating Damage Inspection:Coating damage is a common issue with color steel plates. Scratches, peeling, cracks, and other defects can compromise its protective function. Regularly inspect coating integrity, particularly around doors, windows, corners, and other areas prone to impact. Promptly repair any damage to prevent further corrosion from external environments.

(2) Coating Repair Methods:Minor coating damage can be repaired using touch-up paint matching the plate's original color. Before repairing, clean the damaged area to remove dust, grease, and other contaminants. Lightly sand the surface to enhance coating adhesion. Apply the appropriate touch-up paint evenly, allow it to dry completely, then lightly sand and polish the area to ensure seamless integration with the original coating. For extensive coating damage, contact a professional for repair to guarantee quality results and coating integrity.

Color steel plates are commonly used for roofing or wall cladding, making waterproofing functionality critical. Regular inspection and maintenance of the waterproofing layer are essential to ensure the plates' sealing integrity.

For roofing applications, focus on inspecting seals at roof joints, ridges, and gutters. Ensure sealant remains intact; promptly clean and reapply if cracks or peeling are detected. Simultaneously, maintain unobstructed roof drainage by regularly clearing gutters and downspouts to prevent water accumulation that could corrode the plates. Waterproofing not only prevents rainwater leakage but also extends the service life of color steel plates.

For color steel plates used on walls, regularly inspect the sealing around doors and windows, as well as areas where pipes penetrate walls. Observe these areas for signs of water seepage. If leakage is detected, check the integrity of sealants and waterproof membranes, promptly repairing damaged sections to ensure the wall's waterproofing functionality remains unaffected.

Rust prevention is a critical aspect of color steel plate maintenance, particularly in humid environments.

(1) Preventive Measures:Over time, color steel plates may rust due to environmental exposure. To prevent rust, minimize exposure to humid conditions or areas with high levels of corrosive gases. In harsh conditions, periodically apply rust-proof paint to enhance corrosion resistance. It is generally recommended to reapply rust-proof paint every 2-3 years to maintain optimal protection.

(2) Rust Treatment Methods:Address rust immediately upon detection. For minor rust spots, use a wire brush or sandpaper to remove rust before applying rust inhibitor. For severely rusted areas, replacement of the damaged section and reapplication of rust prevention treatment may be necessary. To prevent rust spread, minimize exposure of the color steel plate to humid environments and conduct regular inspections and maintenance.

(1) Avoid Impact and Scratches: The surface coating of color steel plates is relatively fragile. Prevent contact with hard objects that could cause impact or scratches. Handle with care during transportation to prevent surface coating damage.

(2) Regularly Inspect Undersides: Soil, dust, and debris tend to accumulate beneath color-coated steel plates. Clean undersides periodically to maintain drainage flow and prevent corrosion.

(3) Avoid Prolonged Sun Exposure: While the coating offers some heat resistance, extended exposure to intense sunlight can cause aging and fading. Minimize prolonged direct sunlight exposure.

As a versatile and widely used building material, color steel plates require diligent maintenance. Routine upkeep—including regular cleaning, structural integrity checks, coating repairs, and waterproofing/rust prevention treatments—effectively extends their service life, ensuring sustained performance in buildings and facilities. Regular maintenance not only preserves the plates' aesthetic appeal but also reduces potential repair costs, serving as a critical measure for long-term structural stability and safety.

China galvanized plate manufacturer: Boxing Shuangshengda Steel specializes in galvanized sheet, galvanized steel plate,Colour steel plate etc.We have a full range of product specifications and types, low prices, and more than 20 years of experience, worthy of your trust