Language

▼

Language

▼

More Language

Nano anti-corrosion insulation board is a high-performance building material that combines nanotechnology. It has multiple functions such as anti-corrosion, heat insulation, and weather resistance. It is widely used in construction, chemical industry, shipbuilding, energy and other fields. The following is a detailed introduction to the material:

1. Core features

Anti-corrosion performance

Nano materials (such as nano silicon dioxide, nano zinc oxide, etc.) or nano coatings are used to form a dense protective layer to effectively block moisture, oxygen and corrosive media (such as acids, alkalis, and salts)。

It has a longer life than traditional anti-corrosion materials (such as galvanized steel plates) and is suitable for harsh environments (such as coastal areas and chemical plants)。

Insulation

Nano porous structures (such as aerogels) or low thermal conductivity materials reflect infrared rays and reduce heat conduction.

Insulation in summer (reflecting solar radiation) and insulation in winter (reducing heat loss) have significant energy-saving effects.

Lightweight and high strength

The substrate is often made of aluminum alloy, composite material or special steel. After combining with nano coating, it is light in weight but has high mechanical strength, which is convenient for transportation and installation.

Environmentally friendly and durable

No volatile hazardous substances (VOC), UV aging resistance, long-term use is not easy to fade or performance degradation。

2. Common types

Metal-based nanoplates

Such as nano-coated color steel plates, the surface is coated with anti-corrosion and heat-insulating nanomaterials, used for factory roofs and walls。

Composite nanoplates

Sandwich structures (such as aluminum foil + nano aerogel), both sound insulation and heat insulation, used for cold chain logistics and building exterior walls。

Flexible nanoplates

Bendable nano polymer plates, suitable for pipeline wrapping or special-shaped structure anti-corrosion and heat insulation.

3. Application areas

Construction industry

Roofs, exterior walls, cold storage, mobile cabins, reduce air conditioning energy consumption。

Industrial facilities

Oil storage tanks, chemical plant pipelines, offshore platforms, anti-corrosion and reduce heat loss。

Transportation

Ship cabins, high-speed rail carriages, reduce weight and improve fire resistance。

New energy

Solar panel backplanes, energy storage equipment insulation, improve system efficiency。

4. Common market standards

Coating standards:

ASTM D2201 (spray-coated aluminum), GB/T 23443 (China architectural aluminum coating)。

Corrosion resistance:

C5-M grade (ISO 12944, severe corrosion environment)。

Insulation performance:

Surface resistivity ≥10?Ω (adjustable according to demand)。

5. Precautions

Cost:Nanotechnology materials have high initial investment, but low long-term maintenance costs。

Construction:Professional installation is required to avoid coating damage affecting performance。

Customization: Select different parameters (such as thermal conductivity, temperature range) according to environmental requirements。

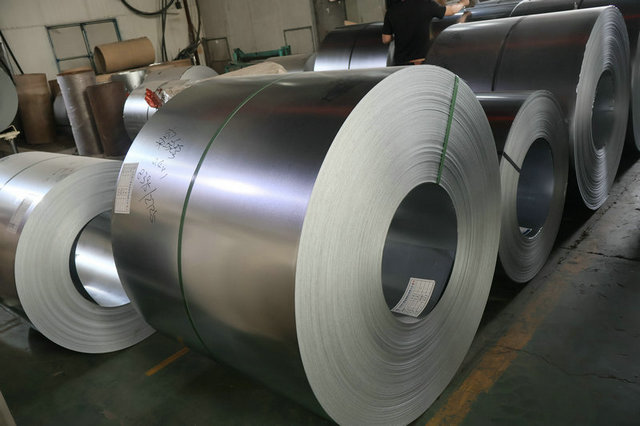

China galvanized plate manufacturer: Boxing Shuangshengda Steel specializes in galvanized sheet, galvanized steel plate,Colour steel plate etc.We have a full range of product specifications and types, low prices, and more than 20 years of experience, worthy of your trust